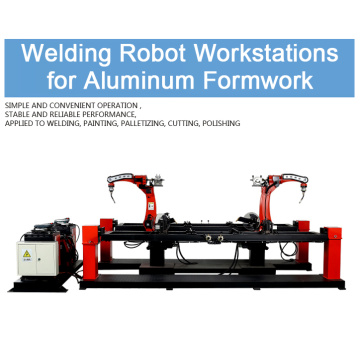

Aluminum Formwork Welding Robot Workstation

Basic Info

Model No.: JS-1006A-ALU

Product Description

Aluminum Formwork Welding Robot Workstation.

This robot welding workstation is specialized designed to weld aluminum form work. The design of positioning machine is reasonable, and it can be customized according to customer needs. It is suitable for welding all kinds of aluminum Formwork. It can carry out welding operation for a long time, repeat positioning accuracy, high welding efficiency, strong stability and high cost performance.

Welding Robots Workstation for Aluminum Formwork

Product Detail

This industrial robot is designed with the control system based on the international-popular open platform for software and hardware, with the specified multi-axes movement control card, data collector card, specified robot connection terminal, and security connector, which are developed independently. Program design is modelized, specified to different tool structure, appled industry, and functions. In structure, this system can control the vertical multi-joint tadem robot, vertical multi-joint parallelogram robot, vertical multi-joint L-shape wrist robot, vertical multi-joint spherical wrist robot, polar coordination robot, Delta robot, and so on. In functions, this system can control the robot to work in the areas, such as lifting, welding, painting, palletizing, cutting, polishing, and so on. Standard computer main wire can extend to on-site main wire, robot vision system, and so on.

Features:

■ Optimized structure algorithm, which can adapt to various structure formation of structure control.

■ Modularized functions settings, which can adapt to various applied scenarios.

■ 6-axies control to realize the control of outside axis (walking axis, positioner).

■ Adaptive to multi-pulse shape, Incremental, absolute servo.

■ Open structure, synchronized internationally, easy to extend.

■ Software PLC functions, easy for logical control.

■ Process function, simplified program operation.

■Improved connecting method of computer main wires for reliability and practicability.

■ Security module for safe production of robot.

| Model | JS-1006A-144 | JS-1006A-180 |

| Number of control axis | 6 axis | 6 axis |

| Maximum working radius | 1400mm | 1800mm |

| User storage space | 200M | |

| Teach | 8-inch TET-LCD, full keyboard, mode-selection switch, security switch + emergency stop (touch screen is optional) | |

| Ports | Digital I/O connector, 24 input/24 output (can be extended) | |

| Security Module | Connected emergency stop, abnormal signal of robot leads to quick stop of robot (optional) | |

| Controllable servo | Incremental, absolute servo: domestic, Taida, Anchuan, Sanling, Sanyang, Songyang, and so on. | |

| Operation mode | Teach, replay, remote | |

| Program mode | Teach replay, process program | |

| Movement functions | Point to point, linear, circle | |

| Instruction system | Movement, logic, process, calculate | |

| Control mode | Position | |

| Coordination system | Joint Coordination, Right-angle coordination, user coordination, and tool coordination. | |

| Software PLC functions | Edited using ladder diagram, 5000 steps | |

| Abnormal detection functions | Emergency stop abnormal, servo abnormal, anti-collision, security maintenance, arc start abnormal, user coordination abnormal, tool coordination abnormal, etc. | |

| Applications | Lifting, welding, painting, palletizing, cutting, polishing, forging and stamping, pouring, etc. | |

| Zero point functions | Absolute:Battery memory;Incremental:reset after opening | |

Renqiu JINSHI Welding Manufacturing Co., Ltd., since its inception on the professional research and manufacture of welding power, it is China's specialized design, development, manufacture, sale of Scaffold making machine key enterprises.

After nearly years of continuous development, the company's Ringlock scaffolding welding machine, Scaffolding automatic cutting machine, Cuplock scaffolding welding machine, Pulley-clip Scaffolding welding machine, kwikstage scaffolding Welding Machine, Steel Prop Automatic Welding Machine, Scaffolding Automatic Punching Machine, Robot Welding Machine has been successfully extended to the market and be recognized.

In the independent development and design on the basis of the introduction of advanced technology at home and abroad to design a high-performance inverter welding machine.

At present, the company sales network throughout the country more than 20 provinces, municipalities and autonomous regions. The company has a sound detection means, welding before leaving the factory to conduct a comprehensive test, welding results qualified, the stability of the factory before the performance indicators with our unremitting efforts to become your final choice is the eternal pursuit of gold lion welder and commitment .

Q1:Do you have your own factory?

We have more than 20 years experience in this field and welcome to our factory for field trips.

Q2:Could you guarantee the quality of your products?

We can promise our QC inspector have done careful scrutiny of each machine before shipping to clients .

Q3:What is the MOQ ?

We can accept 1 sets as the first order.

Q4Can the product be affixed to the buyer's brand?

We can stick customer`s brand on the products if you have request.

Q5:What kind of payment can you accept?

Only T/T is available now.

Product Categories : Robot Welding Machine > Robot Scaffolding Automatic Welding Machine